It's a neat design; a compact 60-contact I2C-based capacitive-touch fretbard. But the connections and communication are undocumented and would be too difficult for me to figure out. Besides which, using this to rebuild a Teensy-based Tri-Bass with new code, touchscreen and wiring would be a lot of effort to go to for a one-off component. So I've been looking around for something else to use...and I think I just found it.

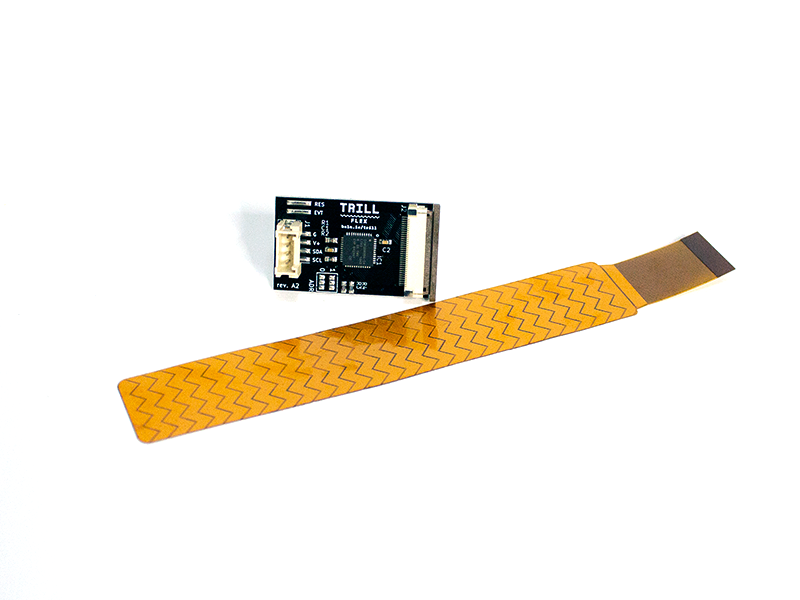

https://bela.io/products/trill/

I've been aware of the Bela Trill range for a while, but I hadn't clocked the fact that the Trill Flex is based around the idea of creating your own custom capacitive touch sensors, with up to 30 contacts. The Tri-Bass fretboard has 60, but I'm thinking I could join two in the middle.

There's a step-by-step guide on how to do it, so I've decided to have a go at this. Just ordered my first gadget of 2023...a Trill Flex..