And so it came to pass that the sun shineth all afternooneth. So I packed everything that was needed and made the epic stroll up the road to Marks house where there was space on the workbench.

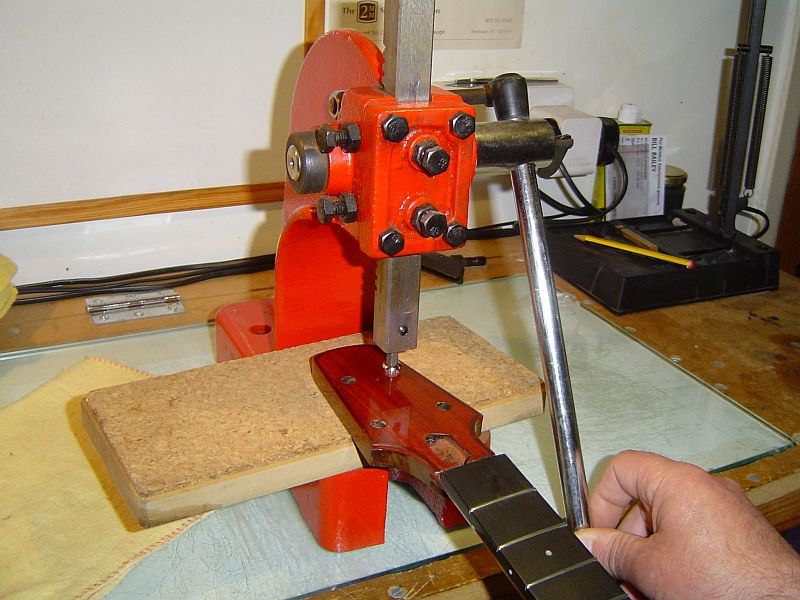

And with coffee on hand I found the bag of cork padding and worked out a nice clamping arrangement.

Frustratingly, I could have done this at home if my bench was 6" deeper !!

Anyway, then it was time to line up the router cutter. I had marked the location of the temporary saddle (the allen key) by making scalpel marks either side at the bass and treble sides. The jig allowed me to align the back of the saddle on base and treble sides with the router bit.

And after some fine tuning I could make the first cut.

After a few passes, going deeper each time, I had to widen the slot. Easiest way is to use feeler gauges to measure the width of the 1st cut, then compare that with the saddle and see how much more you need to add. One important thing to remember is that you fit the saddle to the slot, not the slot to the saddle. So I picked a feeler gauge that added enough extra width without getting as wide as the saddle blank.

And once I had the gauge I used that to space the jig for the second cut.

And after checking and double checking, I made the second cut with a few passes of the Dremel.

And here it is all finished.

Tomorrow I fit the saddle and nut finally, shape them, polish them, and tune up.

And then I need to find the local tenor Uke champion to grab a recording.

Andy